-

Straw: Burn or Build?

October 2013

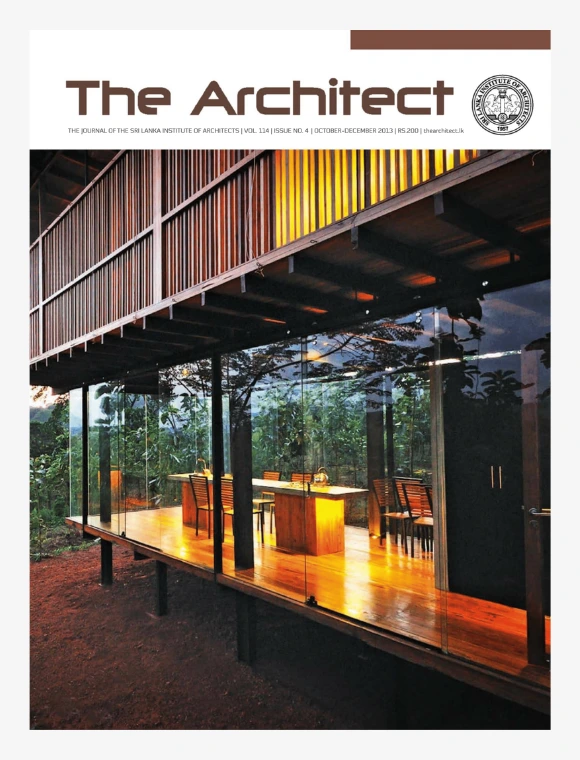

In a world that has been toying with the breaking point of nature’s ecosystem for years, an opportunity to ease human impact while contributing positively to the environment, economy as well as society is not just welcome, it is celebrated. That it resurrects an almost forgotten technology devised centuries ago provides additional endorsement. The use of straw bale in construction is making a comeback as further benefits are uncovered.

By Fatima Abdul Cader

The agriculture industry generates its share of by products including straw, which is produced in abundance. The world is genetically modified enough without the invention of non-straw producing cereal crops to necessitate a more sustainable solution. Alternate purposes for the discarded straw have been created. It is used as livestock bedding, as fodder, as roof thatching, in basket weaving as well as in the manufacture of paper, board and textiles. A broad spectrum of uses, yet we burn excess straw at an alarming rate, aggravating an already volatile planet. This begs the question, are we doing enough?

After much research, straw has once again found its use in construction in the form of straw bale and compressed straw panels. The technology allows buildings a modern finish or a more rustic look. Straw bale is a rectangular 25kg bundle of straw, compressed to an approximately 12 inch high and two feet wide size by local machines. It is bound tightly with polypropylene strings or wire and is laid in two to four bale depths.

Sustainable in production as well as in use, straw bale adapts well to both warm and cold climates due to its thermal insulation properties and high resistance to heat transfer.

Biodegradable and renewable, it scores high on the sustainability scale, with several added benefits making it a popular choice in agricultural regions. Mass scale materials such as cement, concrete and steel incur high energy use that straw bale production does not. It is strong and durable and offers lateral and shear support for wind and seismic loads. In contrast to the highly flammable nature of straw, straw bale is fireproof and minimises flame spread and smoke development.

Sustainable in production as well as in use, straw bale adapts well to both warm and cold climates due to its thermal insulation properties and high resistance to heat transfer. Plastering these walls internally creates excellent thermal mass, providing comfortable room temperatures, minimising energy use in heating and cooling.

Availability of raw materials and simple production methods facilitate an attractively low sunk cost, in addition to low maintenance costs. Owing to its cellulose and nutrient content, straw attracts fewer termites than wood. Assembling straw bale structures are simpler and quicker than other methods, an advantage during disaster relief operations. Their ductility and weight make them a good choice for earthquake prone areas. Interestingly, the material also displays high sound absorption, is bullet proof and resistant to damage from flying debris.

Quality plastering and foundation are cornerstones of durability. Adequate protection from moisture is of critical importance. To overcome this, a raised plinth is used in foundation for a capillary break as are wide roof overhangs. Breathable substances prevent moisture build up, therefore adobe, earth, lime and natural paint are used to plaster walls. The plaster also acts as protection from rodent attacks and gives the designer freedom to create unique textures.

Construction methods are classified as Load Bearing, Non Load Bearing, Hybrid Construction and Compressed Straw Panels. Load Bearing Construction is often referred to as the Nebraska style in reference to its place of origin. With this method, straw bales are piled on each other and carry the load of the roof. In order for the bales to bear the load, they are often laid in three bale thicknesses and limited to single storey constructions. Loads are uniformly distributed, balancing doors and windows on all sides to prevent differential settlement.

To accommodate multiple storeys, a Non Load Bearing Construction method is utilised where the weight of the roof is transferred to a structural frame with bales as infill. Hybrid Construction involves a combination of the above, leveraging the benefits of each for greater design flexibility. Alternatively, straw is compressed under high pressure to create panels of two inch to four inch thickness and used for building interiors or as the building envelope.

Limitations of using straw bale include the need for meticulous pre-planning of plumbing and electrical wiring, which are fixed to the framework, susceptibility to moisture penetration, space consumption owing to thick walls, difficulty in obtaining insurance cover, lack of acceptance as an alternate method with approved codes, shipping costs limit usage to local contexts. However, it proves its mettle as a sustainable method of construction in agricultural regions capitalising on local resources in a harmonious balance.

Resource: Archt Eeshani Mahesan