By Udeshi Amarasinghe | Photography by Eresh Weerasuriya

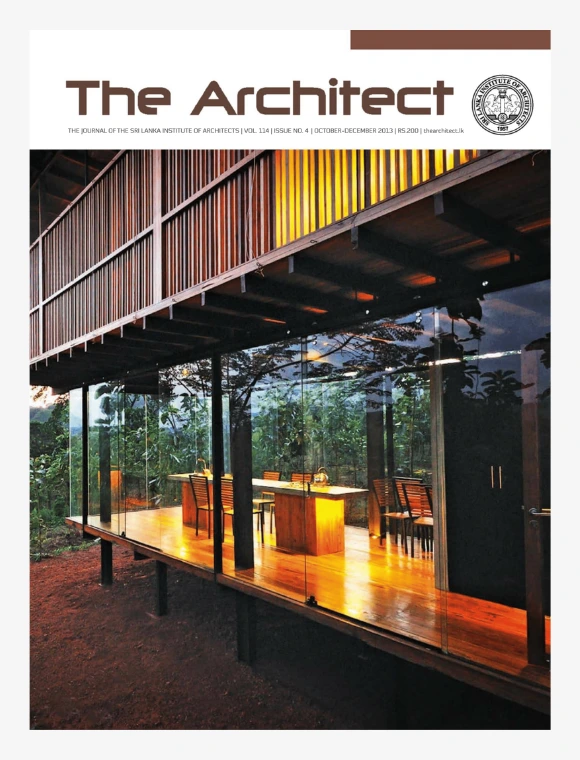

Corporate in design and user friendly in structure, Archt Sanath Liyanage has combined the functional aspects of the building with the beauty of its surrounding and created a space that is truly innovative.

The requirement of the client was to build a collision repair centre that catered to the needs of their Formula Plus insurance scheme holders. As this was the first time such a facility was being introduced to Sri Lanka, the repair centre needed to give a corporate outlook in its design and structure. It was essential that the repair centre be used as a key marketing tool and also to build confidence among its clientele.

Thus giving priority to the need of the client, Archt Liyanage considered the various elements of the site when designing the repair centre. Located in Katugastota the one acre plot is situated on a slope with large trees. A breathtaking view with the Hantana ranges and the river Mahaweli dominated the scenery. “There were many restrictions because of the slope in the land. However the natural environment was used to its advantage in the design of the repair centre – a building complex which included the workshop, worker’s facilities and office,” explained Archt Liyanage.

Since the site had a gradient of almost 10m from the entrance to the lower section, the complex was built as a split level with vehicular access for each level. “The client was expecting about 150 vehicles to repair at any given time so this had to be accommodated,” stated the Architect while adding “the office was to exude the corporate image and was to be the area where customers would be provided with the services and shown around the workshop”.

“I wanted the building to exude simple elegance and clear lines. Furthermore we wanted to minimise the construction period therefore we opted for a steel structure rather than a typical concrete building,” he explained. The steel structure was further enhanced with glass and in fills, which included cement block walls, plaster, aluminium cladding and the roofs were made of Zinc alum of green colour to blend with the rest of the environment. External walls were painted to blend with the rest of the buildings and surroundings.

Upon entering the office building there is double height space, which extends to the ground level that includes an area for inspection, management and engineering. The first floor consists of the customer service office area. “The topmost floor is a penthouse for senior management officers. The penthouse looks out to the Hantana range and the river Mahaweli,” said Archt Liyanage. The workshop consists of three levels including a mezzanine level. The workshop has been built parallel to the length of the site and office building.

Environmentally friendly features such as rain water harvesting have been introduced. The water thus collected is used for gardening and washing vehicles. The waste water from washing the vehicles go through several sand filters and released into the river below.

Solar power was introduced for heating purposes only. Archt Liyanage utilised the natural ventilation flows when designing the building thus only the office area is air-conditioned. The workshop area has no walls and the elevated glass roof on the top of the workshop’s roof allows an additional light to come through and the hot air to flow out. Since the building is on a slope, it transacts wind corridors, thus the building was built parallel to the length of the land.

There are two canteens within the services building, which have been built with open veranda style to optimise the natural light and ventilation. The service building consists of workers facilities such as changing rooms, wash rooms and lockers on the ground floor and training facility on the upper floor.

Presentation of the building has been very important; according to Archt Liyanage “it is similar to walking into a hotel lobby. High end furniture has been used to decorate the space”. Furthermore great efforts have been taken to maintain the clean environment; walls and panels are washable and each bay has been provided with pressurised water and air for convenience of the workers and to ensure that any oil or mud marks are cleared. Concrete surfaces have been left in their raw form to give a rustic look and the floors are cut cement in the workshop whereas the office floors are granite. The wall surfaces are treated to achieve the corporate appearance.

“I believe that architecture should generate from the context and when you look even at this building it has been generated from the surroundings, responding to the elements around it while catering to the need of the contemporary society.” Archt Liyanage stated summing the essence of the Formula World Collision Repair Centre.

Principle Architect/Project Architect: Sanath Liyanage

Structural Engineer: Stems Consultants

Electrical Engineer: Sunil Hapuarachchi

M&E: Nimal Perera

Fire Expert: Sisira Koratuwewatte

Contractors: International Building System Factory Mihira Constructions, Alro, BME Services, Energynet, Westgate International and R.S. Trading

Client: Collision Repair Centre (Pvt.) Ltd.

Construction Period: Fourteen months (July 2007 – September 2008